Will AI and Robotics Replace Human Workers in Manufacturing?

In a world where technology is evolving at lightning speed, the question that looms large in the minds of workers and industry leaders alike is: Will AI and robotics ultimately replace human workers in manufacturing? This topic has sparked significant debate, signaling a paradigm shift in how we envision the future of work. In a recent YouTube video discussion titled “Will AI and Robotics Replace Human Workers in Manufacturing?”, experts delve into the transformative potential of advanced manufacturing technologies. They explore how fully robotic and AI-enabled facilities could redefine the manufacturing landscape, paving the way for a resurgence in American manufacturing prowess—not by shunning automation, but by embracing it.

As we dissect the insights from this engaging conversation, we aim to illuminate the complexities surrounding the role of human workers in an increasingly automated environment. Are the advancements in AI and robotics heralding an era of unprecedented efficiency and innovation, or do they threaten the livelihoods of countless individuals? Join us as we unpack these pressing questions and consider the implications of a future where machines and humans work side by side, reshaping industry norms and redefining what it means to be a worker in the 21st century.

Embracing Advanced Manufacturing: The Future of U.S. Industry

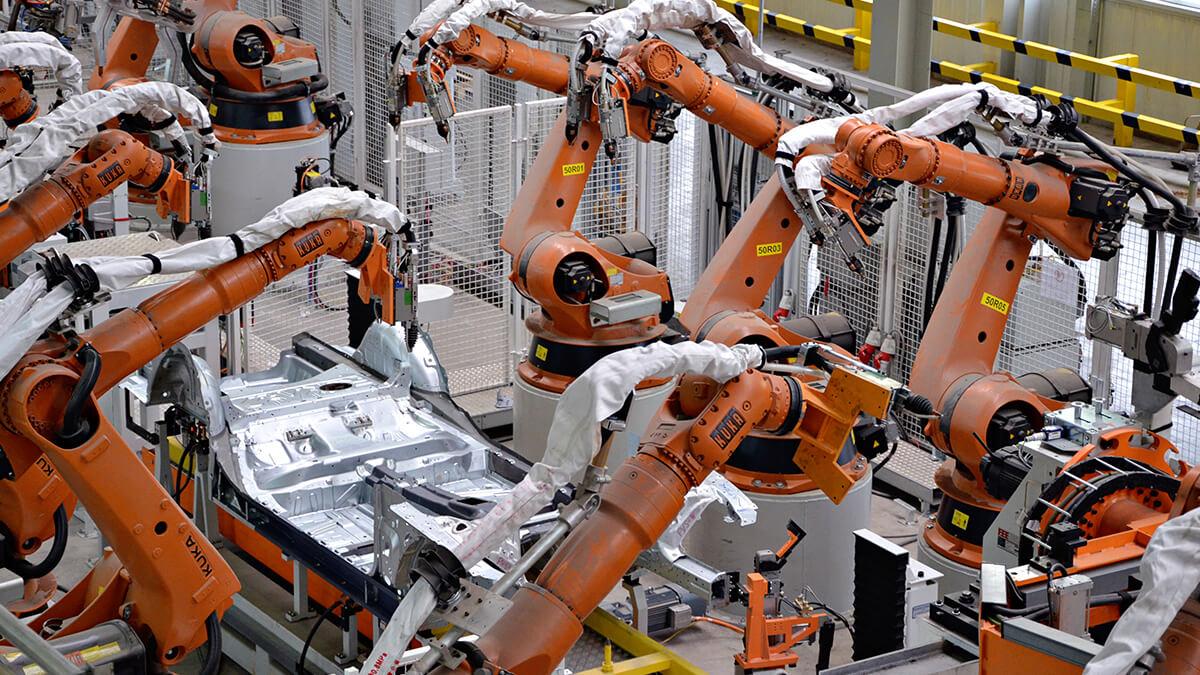

As the landscape of U.S. manufacturing shifts towards advanced technologies, there is a growing recognition that automation, robotics, and AI are not merely tools to reduce labor costs; they represent the backbone of a revitalized industrial strategy. Embracing these technologies could pave the way for the development of fully robotic facilities equipped with sophisticated AI systems, fundamentally altering the mechanics of production. By focusing on scaling up these innovations, America has the opportunity to reclaim its position as a global leader in manufacturing, fostering an environment where efficiency and precision become the hallmarks of industry.

However, the transition to this new era raises critical questions about the workforce of the future. While the fear of widespread job displacement is palpable, it’s essential to acknowledge that new technologies can also create opportunities. Rather than viewing AI and robotics as competitors to human labor, we should consider them as partners in enhancing productivity. A deeper integration of technology in manufacturing could lead to a shift in the types of skills required, emphasizing the need for workers to engage in roles that involve not only programming and maintenance but also strategic decision-making and innovation. This evolution will demand a reimagining of education and training programs to equip the workforce with the necessary skills to thrive in a high-tech environment.

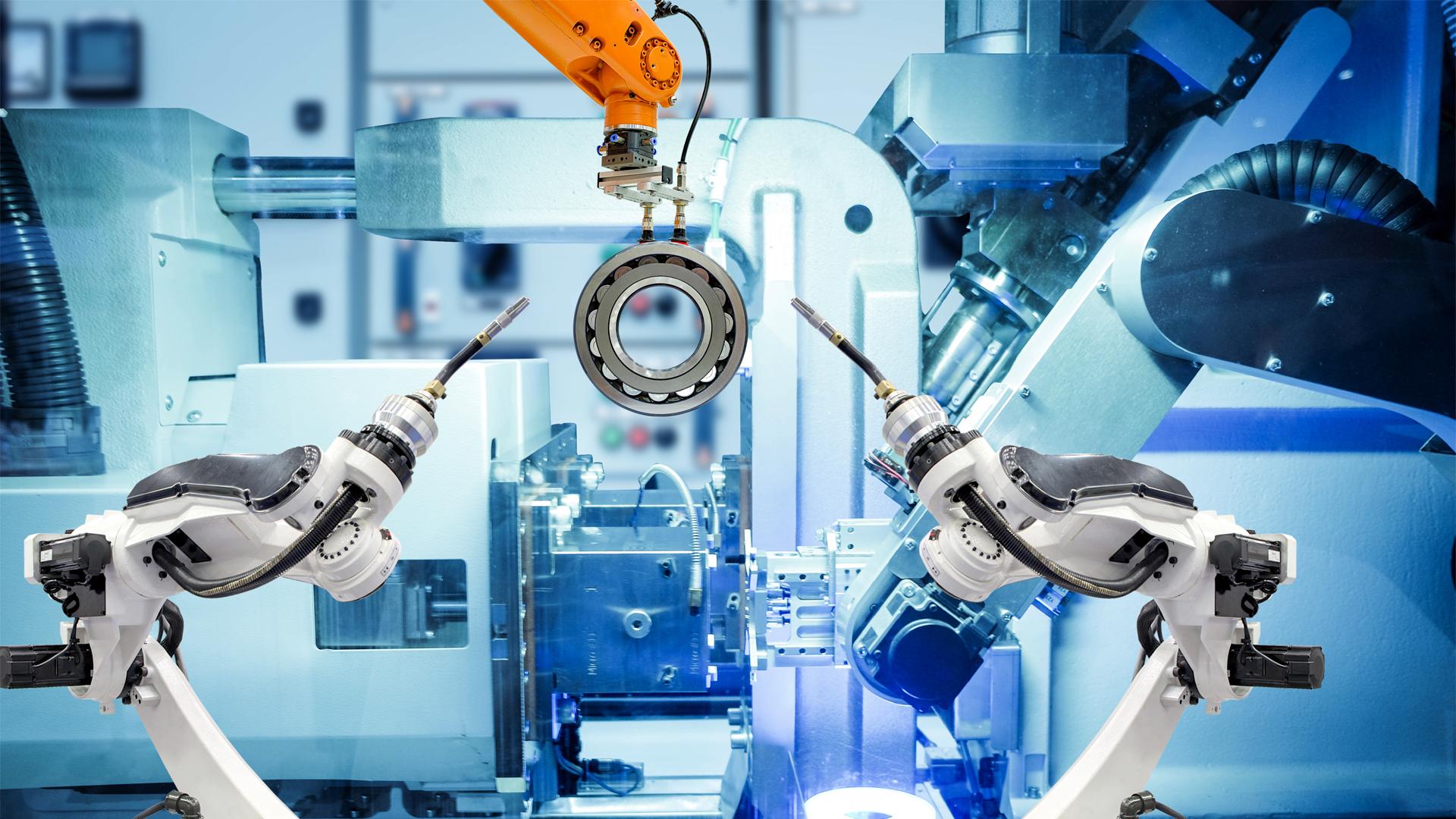

The Role of AI and Robotics in Transforming Production Processes

The transformation of production processes through AI and robotics is nothing short of revolutionary. Advanced manufacturing serves as a pivotal element, allowing businesses to harness the power of sophisticated systems that integrate fully robotic and AI-enabled technologies. This evolution is not merely about replacing manual tasks; instead, it’s about enhancing efficiency, precision, and scalability in manufacturing. As industries adopt these innovations, we witness the emergence of smart factories that operate on data-driven insights, ensuring optimal output while minimizing waste and downtime. The emphasis is on embracing this technology aggressively, with the vision of restoring America as a leading force in global manufacturing.

However, the conversation surrounding the potential replacement of human workers is complex. While automation can take over repetitive and physically demanding tasks, the need for human oversight, creativity, and strategic problem-solving remains essential. A successful integration of robotics and AI involves a collaborative approach where workers transition into roles that leverage their uniquely human skills. Companies can achieve a sustainable future by focusing on upskilling their workforce and redefining job roles to complement the advanced technologies being implemented. In this landscape, rather than disappearing, human workers may evolve and thrive alongside their robotic counterparts.

Navigating the Workforce Transition: Opportunities and Challenges

As we stand at the precipice of a workforce transition, the landscape of manufacturing is set to undergo a radical transformation through the integration of AI and robotics. This shift is not merely a challenge but a significant opportunity for businesses to elevate their operations to a new technological frontier. By adopting fully robotic and AI-enabled factories, companies can create sophisticated systems that enhance efficiency and productivity. Embracing these advancements can position the United States as a leader in manufacturing once again, fostering innovation rather than hindering it. The mantra for this evolution emphasizes that the path forward lies in embracing automation, which could be likened to an “Operation Warp Speed” for the manufacturing sector, driving rapid development and implementation of cutting-edge technologies.

However, this journey is not without its hurdles. The displacement of human workers poses a significant concern, raising questions about the future job market and the skills that will be in demand. Companies must navigate the intricate balance between technological advancement and workforce readiness. Strategies must include:

- Reskilling and Upskilling: Providing training programs to help workers transition into roles that complement new technologies.

- Redefining Job Roles: Identifying and creating new job categories that emphasize human strengths, such as creativity, critical thinking, and problem-solving.

- Partnerships with Educational Institutions: Collaborating with schools and universities to develop curricula that align with the future needs of the manufacturing industry.

As the industry adapts to a more automated future, it is crucial to view these challenges not as barriers but as stepping stones toward a more innovative and sustainable manufacturing ecosystem.

Strategic Recommendations for Businesses Integrating Automation

To successfully integrate automation in manufacturing, businesses should focus on enhancing their technological capabilities while acknowledging the human element of their workforce. This can be achieved through tailored training programs that aim to upskill employees, ensuring they are equipped to work alongside their new robotic counterparts. By fostering a culture of continuous learning and adaptation, organizations can bridge the gap between technology and human expertise. Moreover, companies should consider establishing cross-functional teams that include both technologists and operators to ensure the integration of automation technologies is smooth and efficient. These teams can drive innovation by leveraging insights from diverse perspectives, ultimately leading to more effective solutions.

Investing in advanced automation technologies should be coupled with a strategic roadmap that outlines specific goals and performance metrics. This roadmap can be visualized in a simple table as follows:

| Phase | Objective | Key Performance Indicators (KPIs) |

|---|---|---|

| Assessment | Evaluate current manufacturing processes | Efficiency rate, production downtime |

| Implementation | Introduce automation solutions | Cost reduction, time savings |

| Continuous Improvement | Enhance productivity and quality | Output quality, employee satisfaction |

This structured approach enables businesses to not only embrace automation effectively but also to position themselves as leaders in the competitive landscape of advanced manufacturing. By aligning goals and expectations, companies can maximize the potential of their investments and ultimately thrive in an increasingly automated world.

Key Takeaways

As we wrap up our exploration of the fascinating intersection between AI, robotics, and manufacturing, it’s clear that we stand at a pivotal moment in the industrial landscape. The conversation around whether machines will replace human workers is not simply a binary debate; it’s an invitation to rethink the very nature of work itself. As highlighted in our discussion, embracing advanced manufacturing technologies could propel the U.S. back to its status as a global manufacturing leader—not in spite of automation but because of it.

The potential of fully automated and AI-driven factories promises to enhance efficiency, foster innovation, and ultimately create new opportunities within the workforce. While fears may arise around job displacement, the opportunity lies in upskilling and redefining roles that align with this technological advancement. The analogy of “Operation Warp Speed” for manufacturing emphasizes urgency and strategic focus, suggesting that there is a proactive path we can take to shape the future of work.

In navigating this transformative era, it’s crucial to balance our enthusiasm for new technologies with a thoughtful approach to workforce implications. As this discussion unfolds, let’s continue to engage in these critical conversations, advocate for education and training programs, and ensure that human creativity and ingenuity remain at the heart of our industries.

Thank you for joining us in this exploration. We hope you found the insights shared today as thought-provoking and inspiring as we did. Until next time, let’s keep the dialogue going and remain curious about what the future of manufacturing holds.